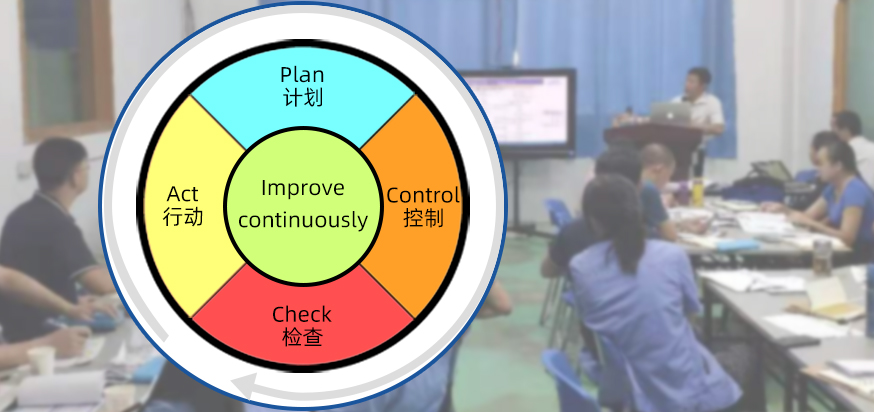

Quality advantage

From tooling to finished products we control and meansure each step to make the

Tooling measurement: Quadratic measurement , oordinates Measuring Machine,and Makino high speed CNC machine ensure the tooling menasurement.

Full set of Detection equipment ensure the product size meet customer requirment.

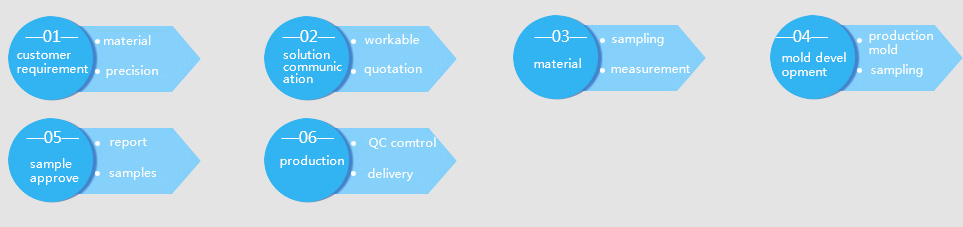

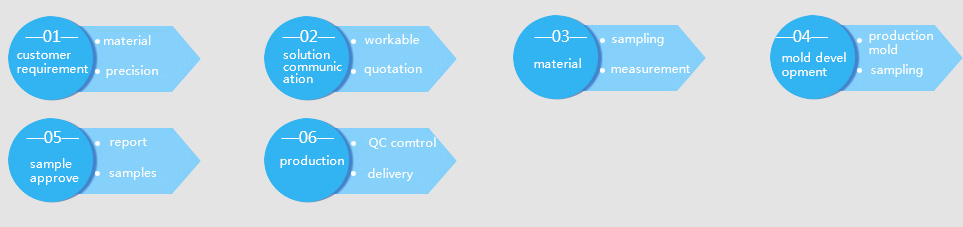

Development process

Customer requirement—Project communication—Material development---tooling design—sample approval-production

Mould Tooling

1.Check drawings (pre-production meeting ) : Discuss the tooling construction reasonable, include shrunk,if have mistake,full size,communicate with client in advance to avoid issue.

2. Mold flow analysis: finish the simulation simulation of injection molding on the computer, simulate the process of mold injection or die casting, obtain the data results, evaluate the feasibility of the mold plan through the results, improve the mold design needs and product design plan

3. Material preparation: order mould frame, core, copper parts, hardware parts and other materials from high-quality suppliers.

4, accessories processing: purchase back to the material subdivision milling machine processing: the first money bed head correction, to ensure that in 0.02m2, the correction of the compression of the workpiece, the first processing screw hole, needle hole thread hole, Australian needle sinking head rent, machine nozzle or material roar, shallow-hole and do the water hole, mirror R Angle

5. Mold processing: numbering, a/B plate processing, panel processing, needle fixing plate processing, bottom plate processing

6, die core processing: first die core t edge, then rough grinding, milling machine plus, fitter processing, CNC rough processing, heat treatment, precision, CNC finishing, edm, save the die!

7, Electric board processing: install the die core on spark tester or CNC machine, adjust the position and fix the die core material for processing

8, die frame parts processing: sliding block processing, compression block processing, casting cone of the flow of just processing, with processing

9. Mold inspection: check whether all the processed motherboard molds and other accessories are qualified and accurate, and whether they are suitable for assembly

10. Mold assembly: assemble the processed mold core, template, spare parts and other accessories.The online supervisor I

11. Flying mold: the whole set of molds will be assembled and fixed

12, test confirmed: the assembly good mold injection mold, computer, machine, molding pressure in products, to see if the product qualified customer requirements, until serving customers confirmation good for "we can try to provide full wrath product video, and 10 try appearance, all the other data report (including mold test reports and test data report), ensure that can produce clear meaning of the product for you